Shrink Bags

The Shrink Bags feature a high resistance and external attractiveness. The bags give the opportunity for longer storage of the product and in this way appear as the perfect packaging for foods with short shelf life. In addition, thanks to the multilayer structure and high barrier properties, they protect and defend the finished product.

Packaging of finished products in thermo shrink bags shall be started in the vacuum chamber machine after which the products are immersed in hot water or be streamed by hot air.

ADVANTAGES:

- High oxygen barrier ensures the long period of storage of the packed production

- Low vapor permeability excludes humidity loss (weight loss) of the product during store

- An attractive appearance of the finished product thanks high compressibility, transparency and finish

- The products packed in shrink bags preserve their natural smell and taste during the whole storing period.

- High strength properties provide safety of the packed products at all stages of transportation and warehousing.

- The absence of chlorine substances in the foil

- EVOH barrier provides the most effective and ecologically safe material nowadays, which possesses the maximum barrier properties in relation to oxygen. The shelf life of the product packed in films with EVOH barrier layer is greatly increased due to this properties. Permeability of EVOH layer for oxygen is approximately equal to permeability of an aluminum layer of the same thickness.

- Optimal gas permeability for SCH45

Bags make it possible to deflate surplus of carbon dioxide and other gases, generated during ripening process, and protect packed products from the oxygen ingress. It ensures high quality of cheese ripening.

RANGE:

| SFR45 | Multilayer bi-axial oriented barrier vacuum shrink bag with EVOH as main oxygen barrier layer. Developed for packaging of fresh and processed meat and poultry products without bones as well non-ripening cheeses.

|

| SLT45 | Multilayer bi-axial oriented barrier vacuum shrink bag, developed for packaging of processed meat, poultry products and non-ripening cheeses.

|

| SLT80 | Multilayer bi-axial oriented barrier vacuum shrink bag, developed for packaging of bone-in meat and poultry products as well products with sharp edges.

|

| SCH45 | Multilayer bi-axial barrier vacuum shrink bag. Developed for packaging of low and medium gassing ripening cheeses.

|

| VT45 | Multilayer barrier vacuum shrink bag with adhesion to the product. Developed for cooking or surface pasteurization of hams and meat products inside the bag. |

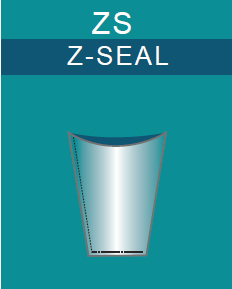

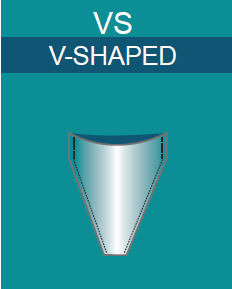

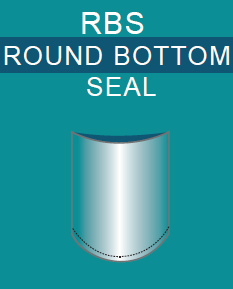

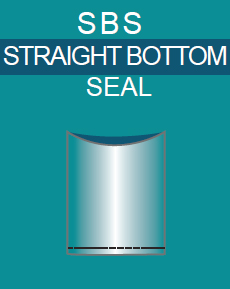

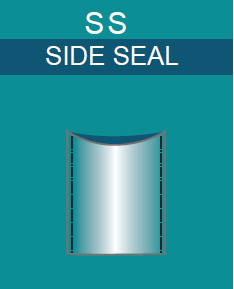

TYPE OF SEALING:

- SS – side seal

- SBS – bottom seal

- RBS – round bottom seal

- VS – v-shaped

- ZS- z-seal

Printed Shrink Bags

Color printed shrink bags provide unlimited possibilities in the advertising to promote products. Printing on package looks contemporary and glamorous. The surface of the packets can be fully encapsulated or brand applied.

Print on the shrink film is provided by using a contemporary flexo printing technology.

Bright, attractive figures as visualization can ensure over 90% of success sell.

ADVANTAGES :

- Company branding and product information can vibrantly and visually be displayed on custom printed vacuum bags

- Vacuum bags provide customer convenience upon purchase.

- Bags can be customized to suit individual brands and product preference.

- Vacuum bags are space convenient and is suitable for effective distribution and storage

- Customized size, structure and design are welcome.

THE PROCESS:

- Development of the layout of the image.

- Approval of the final layout.

- Preparing the cliches-stamp for printing.

- Preparation of the film.

- Flexo printing.

- Bags converting.

Vacuum Bags

Vacuum bags are economical and fast packaging solution when the longer shelf life is on demand. This type of packaging reduces the atmospheric oxygen, and creates an anaerobic environment that limits the growth of aerobic bacteria or fungi, and prevents the evaporation of volatile components. Through this storage method storage times of refrigerated foods, dried foods and frozen foods are extended by creating a hermetic seal similar to the seal that occurs during the canning process.

ADVANTAGES:

- Extremely economical.

- Sealed foods last 3-5 times longer compared to conventional storage methods.

- Vacuum sealing conserves space for food storage.

- Dry, solid foods, such as brown sugar, won’t become hard, because they don’t come in contact with air and, therefore, can’t absorb moisture from the air.

- Insect infestation is eliminated due to a low oxygen environment.

- Meat and fish will marinade in minutes, because as air is being removed from the canister, the pores of the mat or fish open up and allow the marinade to penetrate.

- Seal dehydrated foods and dried herbs for longer term storage.

- Non-food items are protected from oxygen, corrosion and moisture-damage. For example you can vacuum seal unused oxygen absorbers, matches, socks for bug out bag, medication, emergency forms, etc.

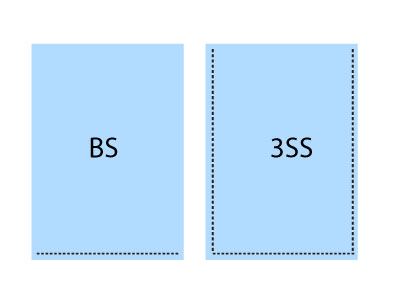

TYPE OF SEALING:

- BS – bottom seal

- 3SS – 3 side seal